- Inspection & Live Extended Depth of Field (EDF)

- Inspection & Quality Assurance

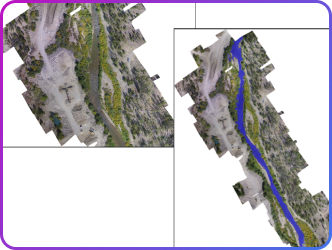

- Aerosol Spray & Spot Analysis

- Intermetallic Corrosion

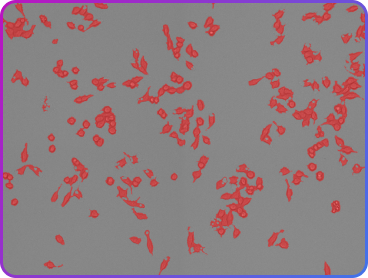

- Particle Analysis

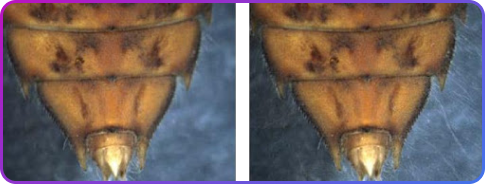

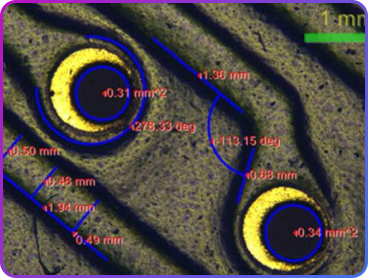

- Metrology

- Image Stack Alignment

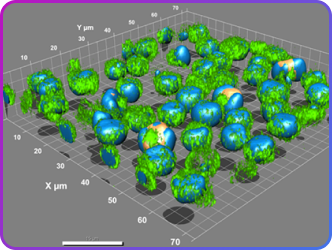

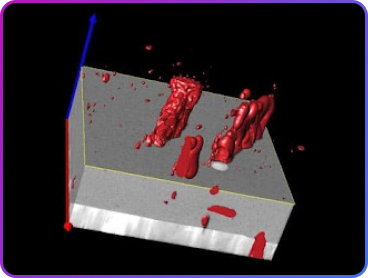

- 3D Visualization & Volume Analysis

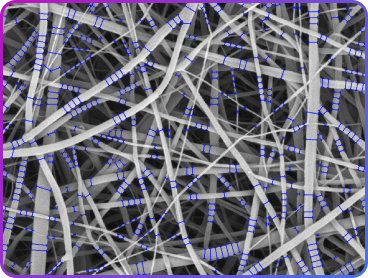

- Textile & Fibers

Capture beautifully focused images, regardless of depth, with Live EDF.

Whether using a stereo, brightfield, or fluorescent microscope, an automated z-motor is not required.

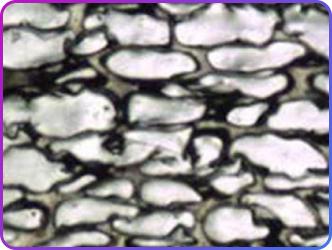

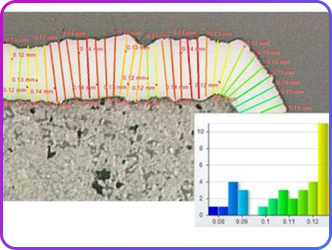

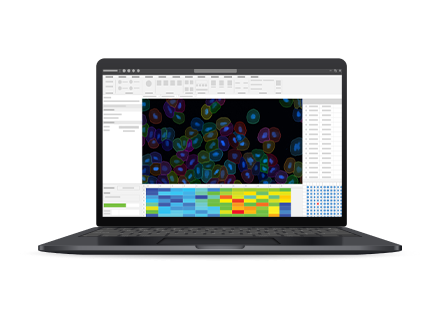

Supported by a wide range of manual measurement and automated measurement features, Image-Pro can quickly be set up to analyze pores or tubing diameters. Advanced data display tools can quickly give a visual reference to measurements outside of a nominal range as in the analysis of a mesh material.

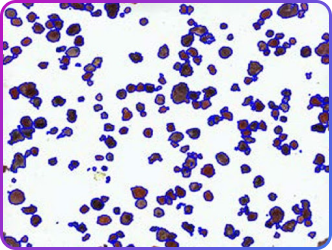

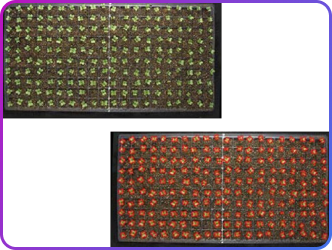

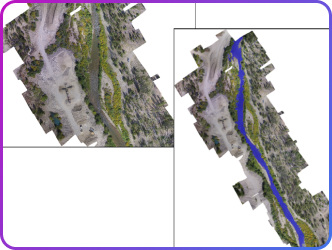

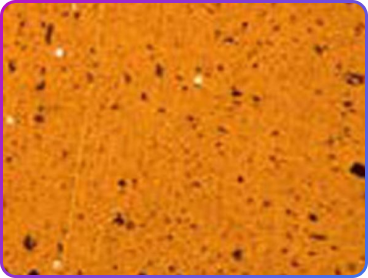

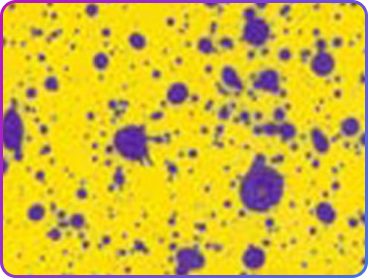

Water- and oil-sensitive paper provides a convenient way for evaluating spray nozzle effectiveness in both industrial and agricultural applications. When counting and analyzing spray drops, Image-Pro can be used to measure droplet density, spray distribution, and spray patterns.

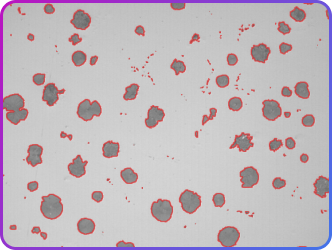

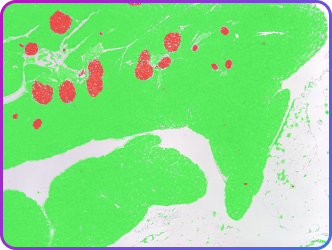

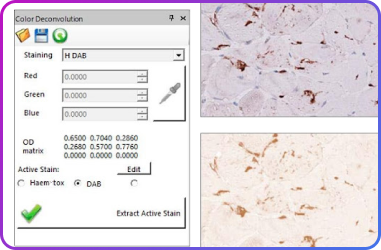

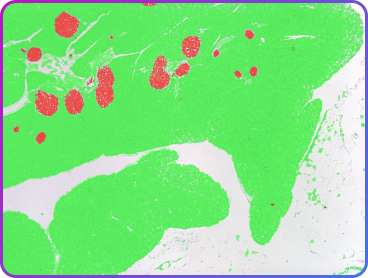

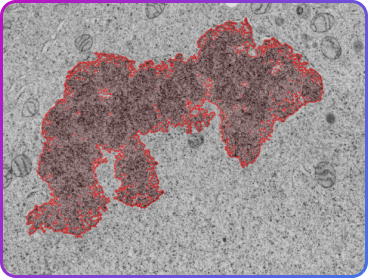

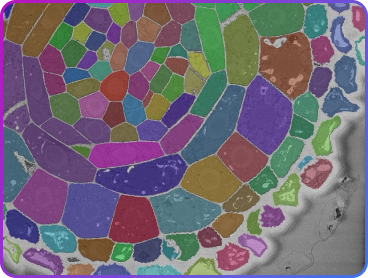

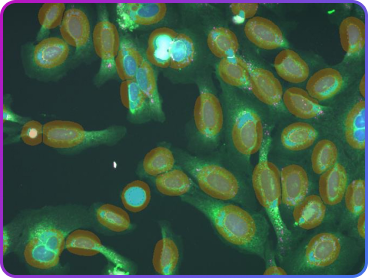

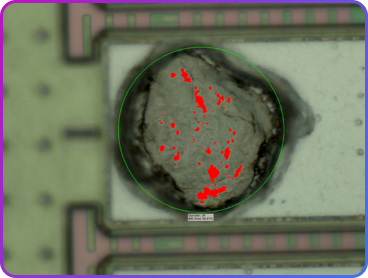

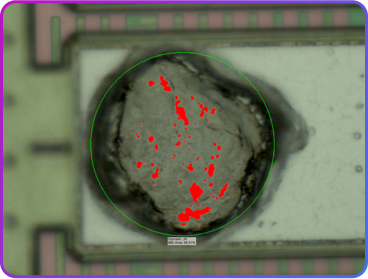

Analyze Intermetallic Corrosion (IC) by examining electronic contact areas on IC contacts.

Look for corrosion between copper ball ends and aluminum contact sites within a region of interest (ROI) drawn over the point of contact. With a custom segmentation threshold, you can then identify the uncorroded aluminum.

With that information, report the percentage area of the ROI not containing uncorroded aluminum – that is, the percentage area covered in corrosion products.

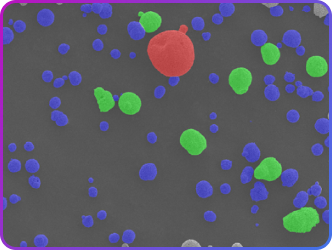

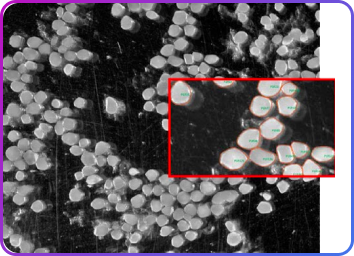

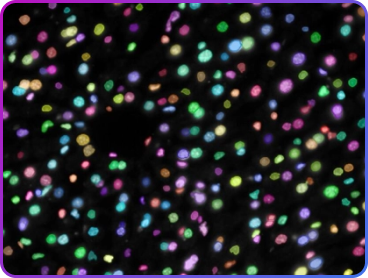

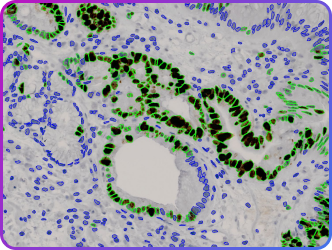

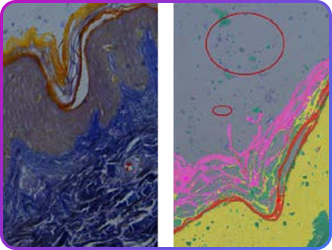

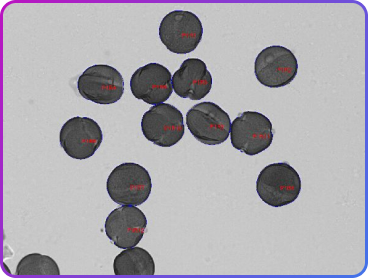

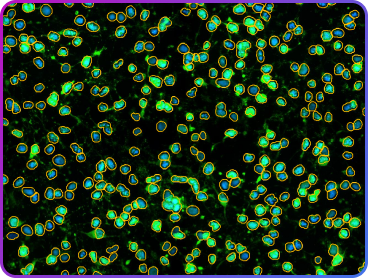

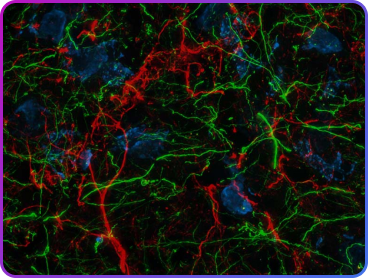

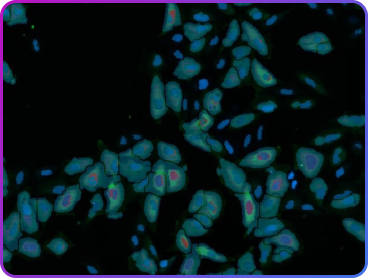

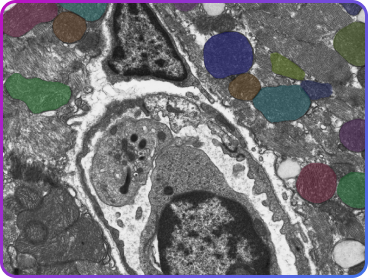

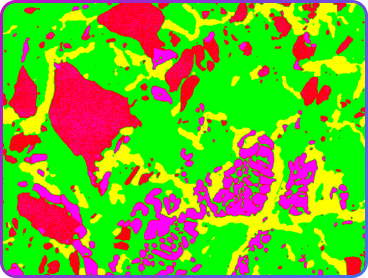

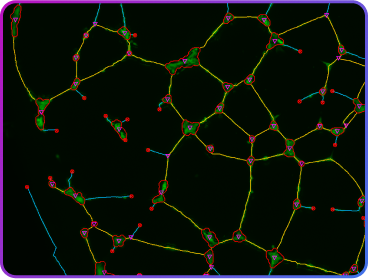

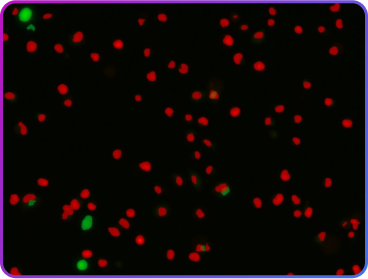

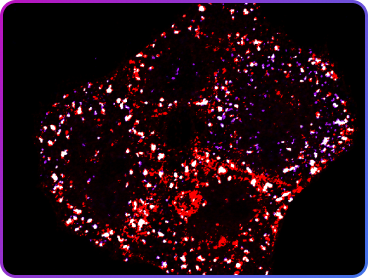

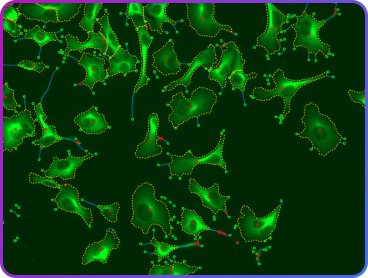

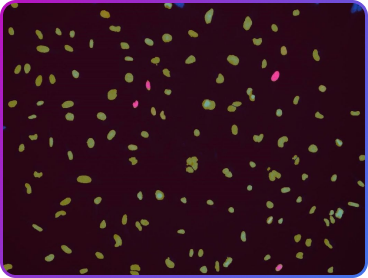

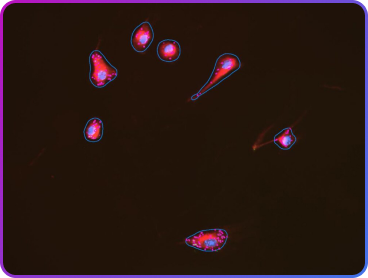

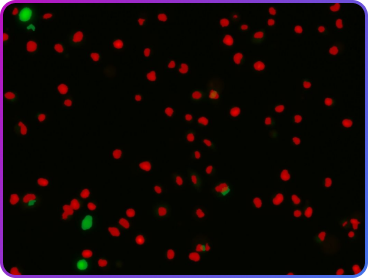

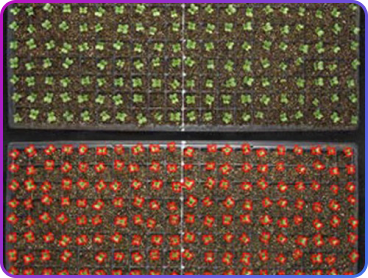

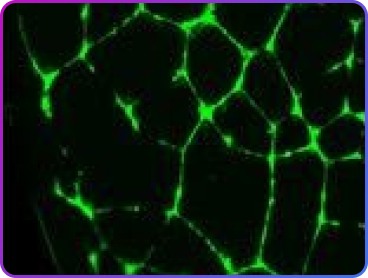

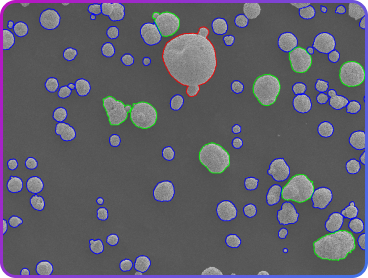

Particle analysis, whether used for manufactured materials or quantifying potential contamination, requires a sophisticated machine learning segmentation technique called Smart Segmentation. Smart Segmentation allows you to reliably find and quantify the particles in a wide range of difficult imaging environments.

Once the particles have been measured, additional distribution analysis or particle classification may be reported.

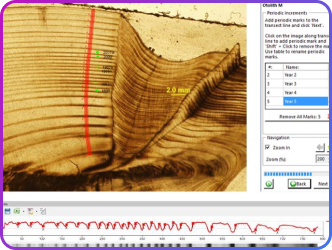

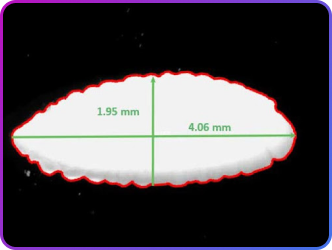

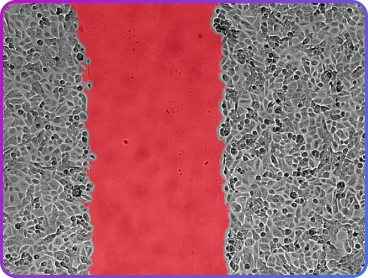

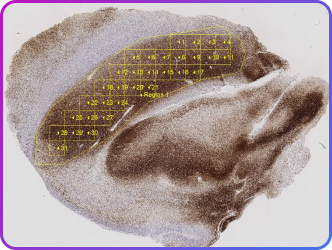

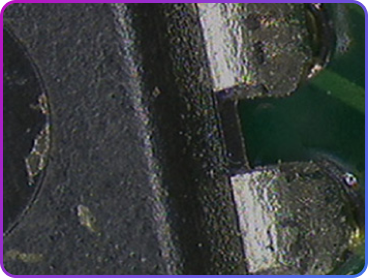

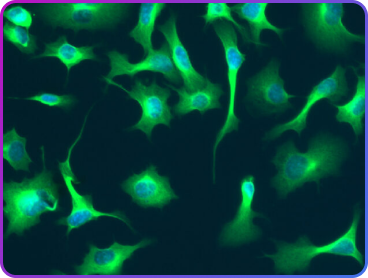

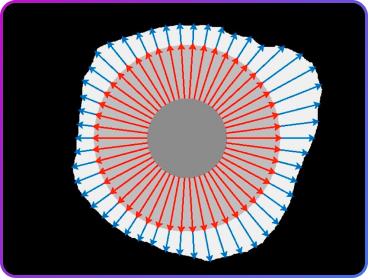

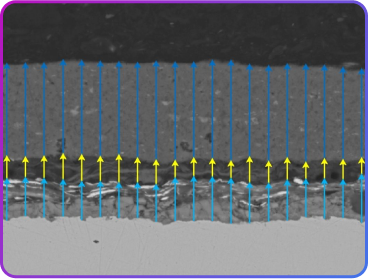

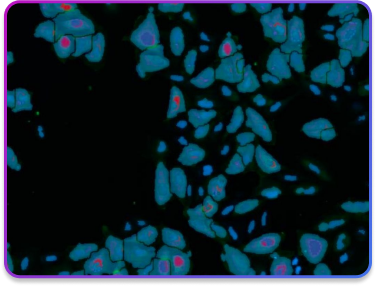

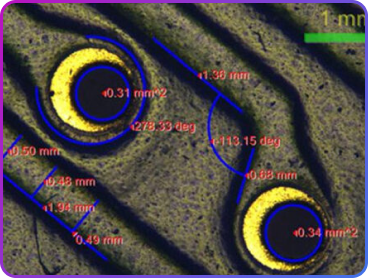

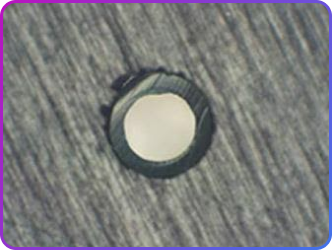

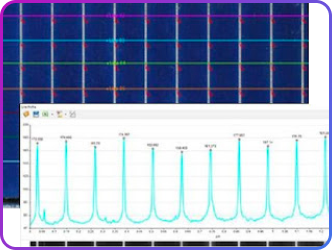

In many industries, testing and quality assurance depends on automatically locating specific features and performing measurements on those specific features.

Image-Pro includes automated edge detection tools such as Caliper to accurately determine specific edge features and measure the distances between them.

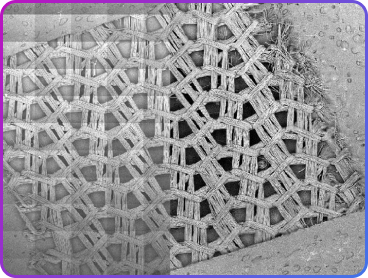

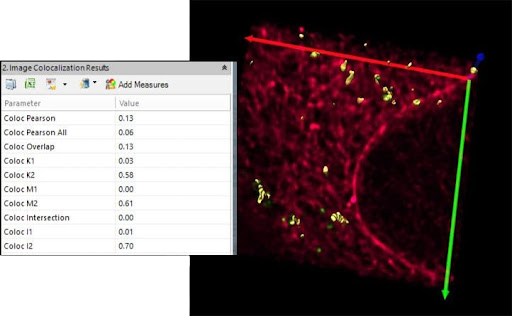

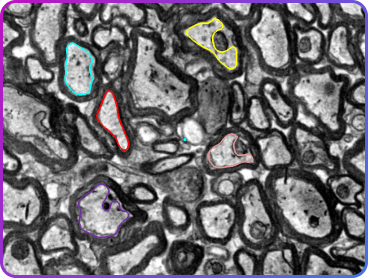

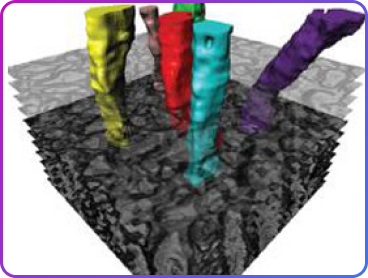

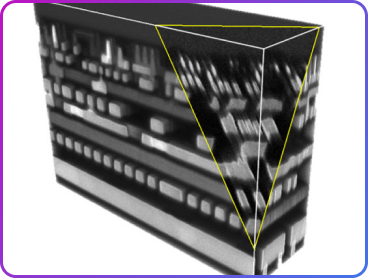

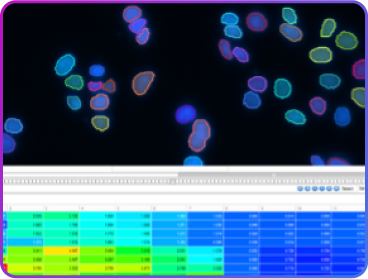

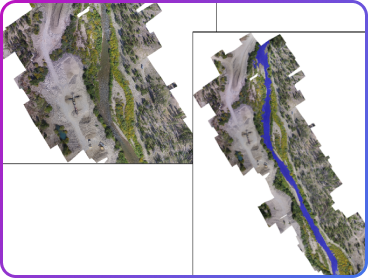

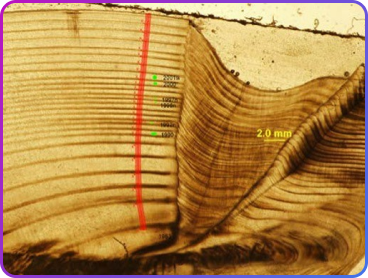

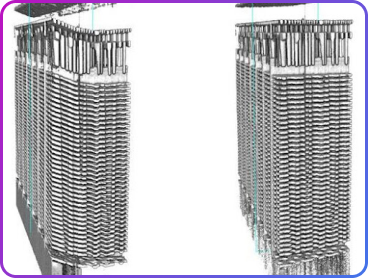

Before and after image stack alignment of NAND flash memory block using FIB-SEM imaging. In some cases, the 3D image stack must be correctly aligned before 3D volume rendering and analysis can occur.

If the image planes are misaligned, critical dimension analysis may generate incorrect results. Image-Pro includes specific image stack alignment methods to correctly align the image stack.

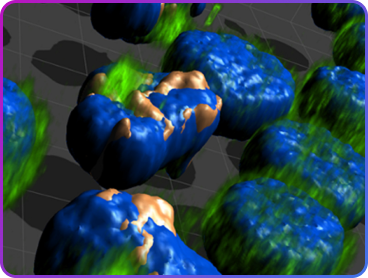

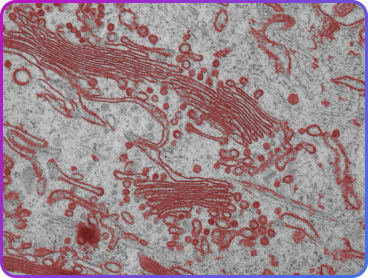

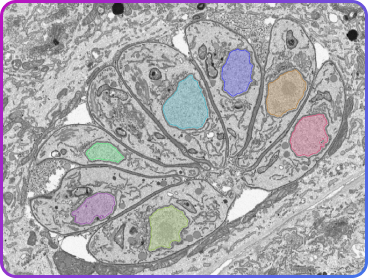

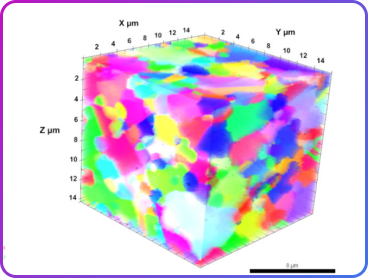

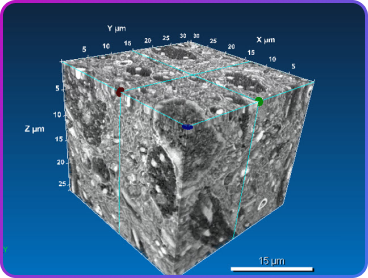

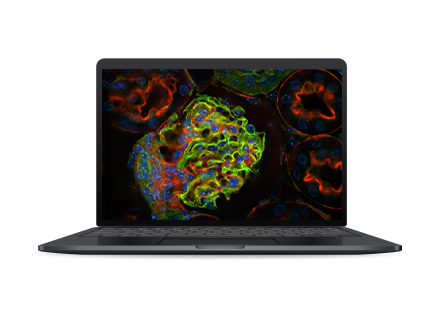

In addition to microtome techniques used in SEM imaging to general 3D image stacks, FIB-SEM, focus ion beam, is another technique used in the semiconductor industry.

With FIB-SEM imaging, large 3D image data sets can be rendered and viewed as 3D volumes.

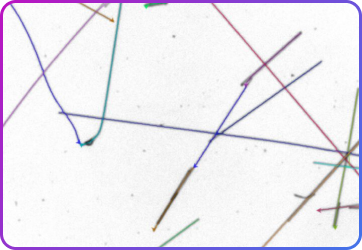

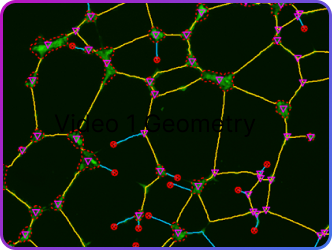

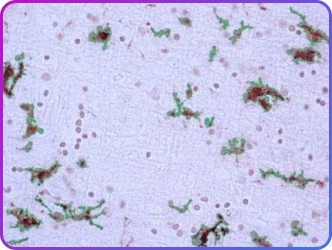

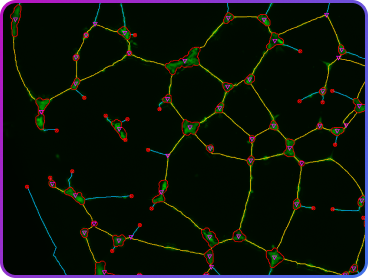

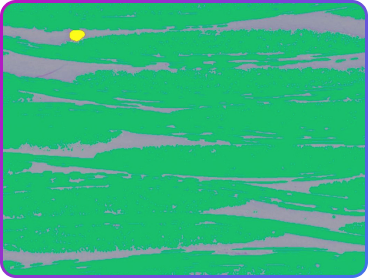

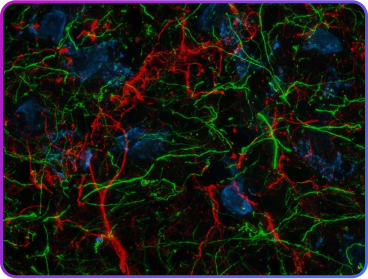

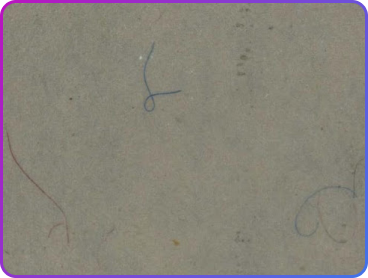

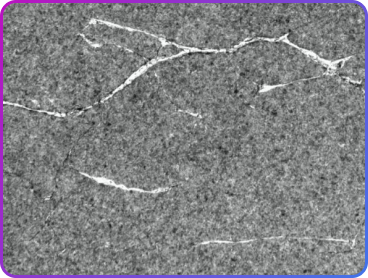

Carbon, natural or synthetic fibers are used in a variety of manufactured goods and industries.

Use the Fiber Separation and Fiber Thickness protocols to quickly measure fiber length, thickness – even with overlapping fibers.

Explore Image-Pro by Industry

Explore Image-Pro by Industry